Transmission Steel Tube Ntauwd

Transmission Steel Tube Ntauwd

Cov qauv kev sib kis yog ib qho ntawm cov ntsiab lus pom zoo tshaj plaws ntawm cov hluav taws xob xa hluav taws xob. Lawv txhawb nqa cov conductors siv los thauj hluav taws xob los ntawm cov khoom tsim los rau cov neeg siv khoom thauj khoom. Cov kab xa hluav taws xob nqa hluav taws xob hla qhov deb ntawm high voltages, feem ntau ntawm 115 kV thiab 765 kV (115,000 volts thiab 765,000 volts).

Muaj ntau ntau qhov sib txawv tsim rau cov qauv sib kis. Muaj ob hom yog:

1. Lattice Steel Towers (LST), uas muaj cov txheej txheem steel ntawm tus kheej cov khoom siv uas yog bolted lossis welded ua ke

2. Tubular Steel Ncej (TSP), uas yog hollow steel ncej fabricated xws li ib thooj los yog raws li ob peb daim haum ua ke.

Cov qauv loj sib txawv nyob ntawm qhov voltage, topography, ncua ntev, thiab ntauwd hom. Piv txwv li, ob-circuit 500-kV LSTs feem ntau yog los ntawm 150 mus rau ntau tshaj 200 feet siab, thiab ib-circuit

500-kV yees feem ntau yog los ntawm 80 txog 200 feet siab. Ob chav-circuit qauv yog siab dua ib-circuit qauv vim hais tias cov theem yog teem vertically thiab cov theem qis tshaj yuav tsum muaj ib tug tsawg kawg nkaus hauv av clearance, thaum lub theem yog teem horizontally ntawm ib-circuit lug. Raws li qhov hluav taws xob nce, cov theem yuav tsum tau sib cais los ntawm kev ncua deb kom tsis txhob muaj kev cuam tshuam los yog arcing. Yog li, ntau dua voltage yees thiab ncej yog siab dua thiab muaj dav kab rov tav hla caj npab dua li cov qauv qis dua.

DESIGN SPECIFICATION:

| Khoom | Fais Fab Kis Kab Hlau Hlau Tube Ntauwd |

| Qhov siab | Los ntawm 10M-100M los yog raws li tus neeg yuav tsum tau muaj |

| Haum rau | Hluav taws xob xa hluav taws xob thiab xa tawm |

| Cov duab | Polygonal los yog conical |

| Khoom siv | Nquag Q235B / Q355B |

| Lub Zog Muaj Peev Xwm | 10kV 11kV 33kV 35kV 66kV 110kV 132kV 220kV 330kV 500kV los yog lwm yam customized voltage |

| Tolerance ntawm qhov loj me | Raws li tus neeg thov kev thov |

| Kev kho saum npoo | Kub-dip-galvanized tom qab ASTM123, lossis lwm yam qauv |

| Sib koom ntawm Poles | Kev sib koom ua ke, flanged txuas |

| Txuj | ISO9001: 2015 |

| Ntev ntawm ib ntu | Hauv 13M ib zaug tsim |

| Vuam Standard | AWS (American Welding Society)D 1.1 |

| Txheej txheem ntau lawm | Raw khoom kuaj-txiav-bending-welding-dimension xyuas-flange vuam-qhov drilling-piv txwv sib dhos-nto huv-galvanization lossis lub zog txheej / pleev xim-recalibration-pob |

| Pob ntawv | Ntim nrog ntawv yas los yog raws li tus neeg yuav tsum tau muaj |

| Lub Sijhawm Lub Neej | Ntau tshaj 30 xyoo, nws yog raws li kev txhim kho ib puag ncig |

KHOOM PLIG:

Rau cov xaim hluav taws xob hauv ntau lub sijhawm, koj tuaj yeem tuaj rau kev sib tham nrog kev sib tham, pab pawg tsim qauv thiab kev pabcuam ib-nres tau muab!

Peb xav tau cov neeg siv khoom los muab cov kev ntsuas hauv qab no:cua ceev, voltage theem, kab rov qab ceev, tus neeg xyuas pib loj thiab ncua

Khoom siv:

Txhawm rau kom ntseeg tau cov khoom zoo, peb pib los ntawm kev yuav khoom ntawm cov khoom siv raw. Rau cov khoom siv raw, lub kaum sab xis steel thiab cov kav hlau uas xav tau rau kev ua cov khoom lag luam, peb lub Hoobkas yuav cov khoom ntawm cov chaw tsim khoom loj nrog kev ntseeg tau zoo thoob plaws hauv lub tebchaws. Peb lub Hoobkas tseem yuav tsum tau tshuaj xyuas cov khoom siv raw kom zoo kom ntseeg tau tias cov khoom siv raw khoom zoo yuav tsum ua tau raws li lub teb chaws tus qauv thiab muaj daim ntawv pov thawj ntawm lub Hoobkas thiab daim ntawv tshuaj ntsuam xyuas.

KEV PAB CUAM:

1. Tus neeg xa khoom tau tso cai hauv Pakistan, Egypt, Tajikistan, Poland, Panama thiab lwm lub tebchaws;

2. Lub Hoobkas tau ua tiav kaum tawm txhiab tus neeg ua haujlwm txog tam sim no, yog li ntawd peb muaj kev nplua nuj ntawm kev khaws cia;

3. Kev txhawb nqa yooj yim thiab tus nqi qis zog ua rau cov khoom lag luam muaj txiaj ntsig zoo hauv ntiaj teb.

4. Nrog rau pab neeg tsim duab kos duab thiab kos duab, koj tuaj yeem tso siab rau koj xaiv.

5. Cov kev tswj xyuas nruj nruj thiab cov peev txheej kev lag luam ntau tau tsim cov khoom lag luam hauv ntiaj teb.

6. Peb tsis yog tsuas yog cov tuam ntxhab thiab cov muag khoom, tab sis kuj yog koj cov neeg koom tes thiab kev txhawb nqa.

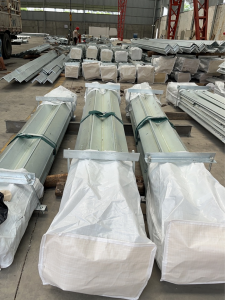

ASSEMBLY & TEST NTAWM STEEL TOWERS:

Tom qab kev tsim cov hlau ntauwd tiav, txhawm rau kom ntseeg tau tias qhov zoo ntawm cov hlau ntauwd, tus neeg soj ntsuam zoo yuav tsum ua qhov kev xeem sib dhos ntawm nws, nruj me ntsis tswj qhov zoo, nruj me ntsis tswj cov txheej txheem tshuaj xyuas thiab cov qauv, thiab nruj me ntsis tshuaj xyuas qhov machining dimension. thiab machining raug raws li cov kev cai ntawm phau ntawv zoo, thiaj li yuav xyuas kom meej tias lub machining raug ntawm cov khoom raws li tus qauv yuav tsum tau.

Lwm Cov Kev Pabcuam:

1. Tus neeg siv khoom tuaj yeem tso siab rau lub koom haum kuaj thib peb los kuaj tus pej thuam.

2. Chaw nyob tuaj yeem muab rau cov neeg siv khoom uas tuaj rau hauv lub Hoobkas tuaj xyuas cov pej thuam.

Kub DIP GALVANIZATION:

Tom qab kev sib dhos & kev sim, cov kauj ruam tom ntej yuav ua tiav:kub dip galvanizing, uas aims ntawm kev zoo nkauj, tiv thaiv xeb thiab prolonging lub neej kev pab cuam ntawm lub steel ntauwd.

Lub tuam txhab muaj tus kheej galvanizing cog, pab neeg ua haujlwm galvanizing, cov kws qhia paub txog galvanizing rau kev taw qhia, thiab kev ua haujlwm nruj raws li ISO1461 galvanizing tus qauv.

Cov nram qab no yog peb galvanizing parameter rau siv:

| Txuj | Galvanized txheej txheem: ISO: 1461 |

| Yam khoom | Thickness ntawm zinc txheej |

| Standard thiab yuav tsum tau | ≧86m |

| Lub zog ntawm adhesion | Corrosion los ntawm CuSo4 |

| Zinc tsho tiv no tsis raug stripped thiab tsa los ntawm hammering | 4x ua |

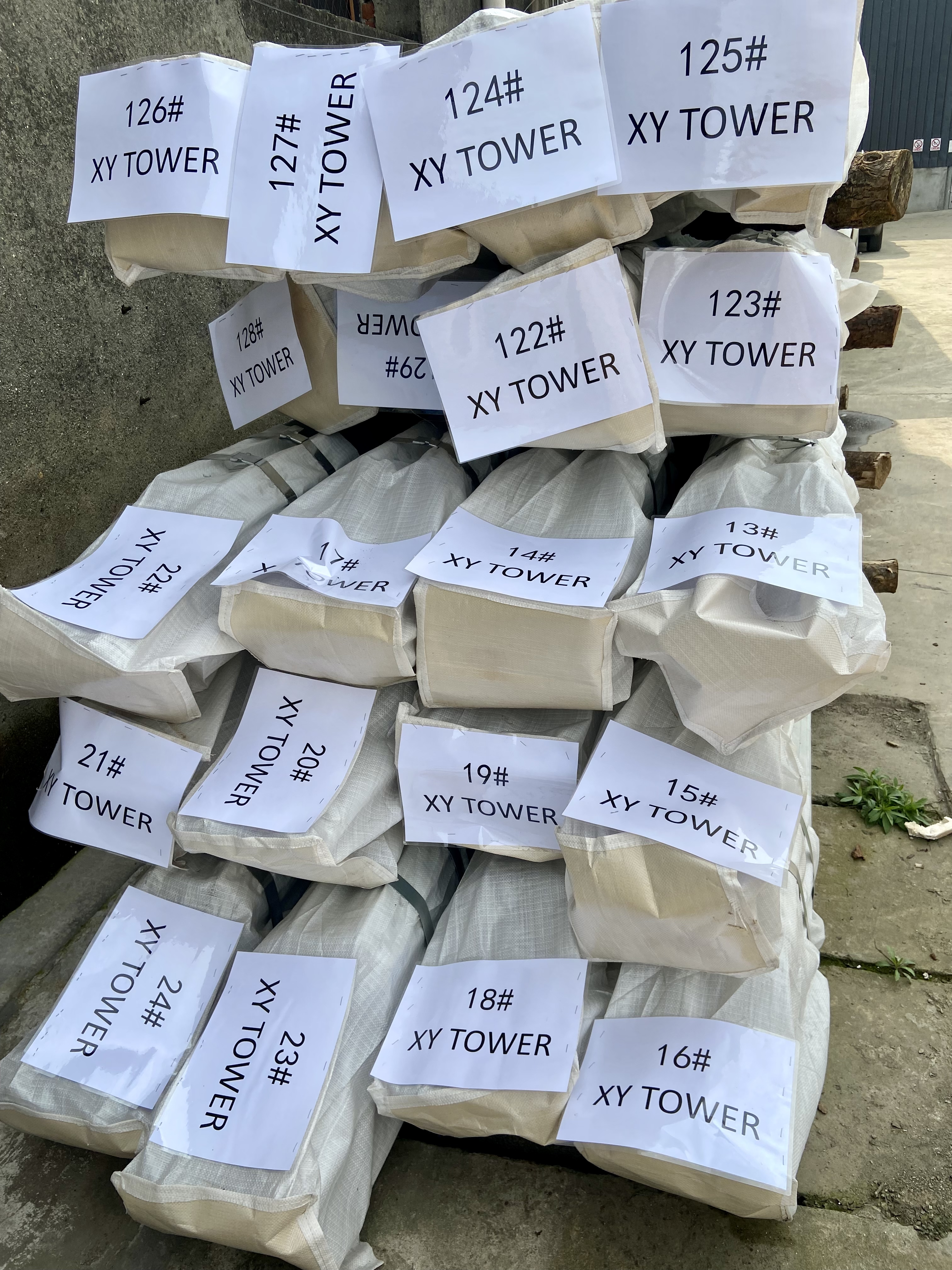

PACKAGE:

Tom qab Galvanization, peb pib pob, Txhua daim ntawm peb cov khoom yog coded raws li cov lus piav qhia. Txhua tus lej yuav muab tso rau ib lub foob rau ntawm txhua daim. Raws li txoj cai, cov neeg siv khoom yuav paub meej tias ib daim ntawv muaj nyob rau hom twg thiab ntu.

Tag nrho cov khoom raug suav tau kom raug thiab ntim los ntawm kev kos duab uas tuaj yeem lav tsis muaj ib daim uas ploj lawm thiab yooj yim rau nruab.