Telecom Communication Angle Steel Ntauwd

Peb Ua Dab Tsi

XY Towersyog lub tuam txhab ua lag luam ntawm high voltage kis kab mob nyob rau sab qab teb sab hnub poob Tuam Tshoj.Tsim nyob rau hauv 2008, raws li ib tug tsim thiab pab tswv yim tuam txhab nyob rau hauv lub teb ntawm hluav taws xob thiab kev sib txuas lus Engineering, nws tau muab EPC kev daws teeb meem rau kev loj hlob xav tau ntawm Transmission thiab Distribution (T & D) sector hauv cheeb tsam.

Txij xyoo 2008, XY yeestau koom nrog qee qhov loj tshaj plaws thiab nyuaj tshaj plawshluav taws xobKev tsim kho cov haujlwm hauv Suav teb.Tom qab 15 xyoo ntawm kev loj hlob tsis tu ncua.peb muab cov kev pabcuam hauv kev tsim hluav taws xob uas suav nrog kev tsim thiab muab cov kab sib txuas & xa tawm thiab hluav taws xob substation.

Yam khoom tshwj xeeb

| Khoom npe | Angular Hlau LatticeTelecom Ntauwd |

| Raw Khoom | Q235B/Q355B/Q420B |

| Kev kho saum npoo | Kub dip galvanized |

| Galvanized Thickness | Nruab nrab txheej thickness 86um |

| Kev pleev xim | Customized |

| Bolts | 4.8; 6.8; 8.8 |

| Daim ntawv pov thawj | GB/T19001-2016/ISO 9001:2015 |

| Lub neej | Ntau tshaj 30 xyoo |

| Manufacturing Standard | GB/T2694-2018 |

| Galvanizing Standard | ISO 1461 |

| Raw Material Standards | GB/T700-2006, ISO630-1995, GB/T1591-2018; GB/T706-2016; |

| Fastener Standard | GB/T5782-2000. ISO4014-1999 |

| Vuam Standard | AWS D1.1 |

| Tsim Cua Ceev | 30M / S (nws txawv los ntawm cheeb tsam) |

| Icing Qhov tob | 5mm-7mm: (nws txawv los ntawm cheeb tsam) |

| Aseismatic Intensity | 8 ° |

| Preference Kub | -35ºC ~ 45ºC |

| Ntsig Ntsig | <1/1000 |

| Av Resistance | ≤ 4Ω |

Cov qauv

| Txuj kev tsim khoom | GB/T2694-2018 |

| Galvanizing tus qauv | ISO 1461 |

| Cov qauv raw khoom | GB/T700-2006, ISO630-1995, GB/T1591-2018; GB/T706-2016; |

| Fastener txheem | GB/T5782-2000. ISO4014-1999 |

| Vuam txheem | AWS D1.1 |

| EU tus qauv | CE: EN10025 |

| American Standard | ASTM A6-2014 1 |

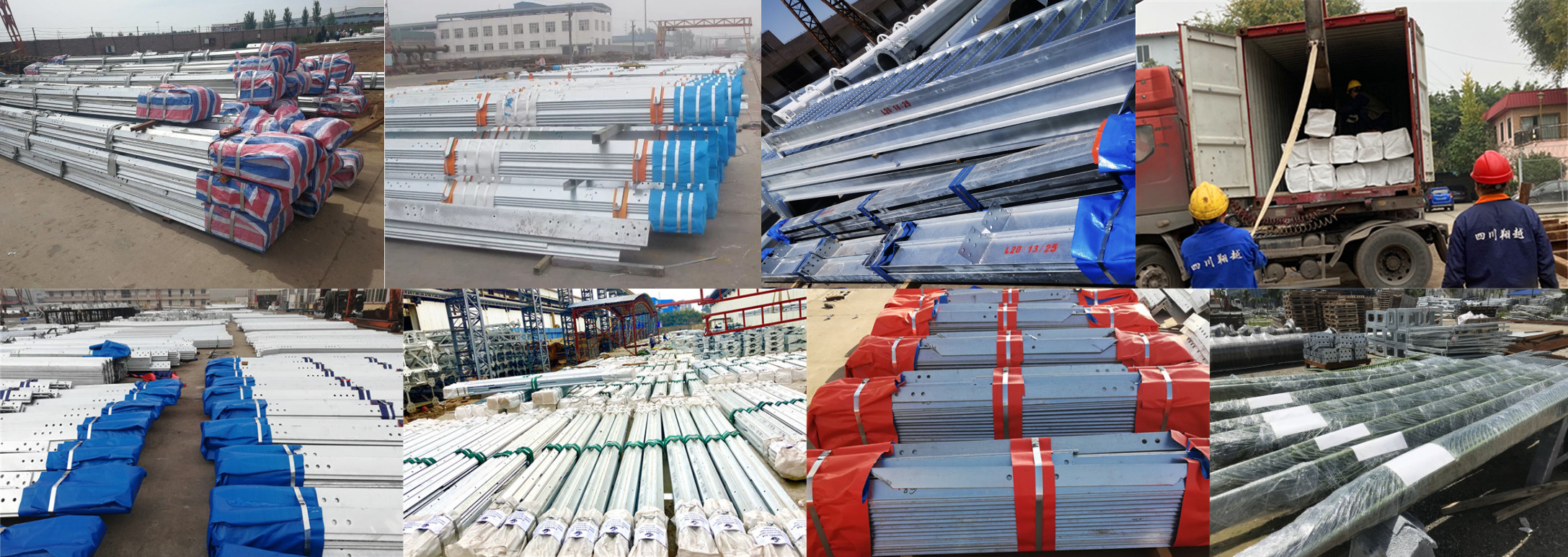

Production Show

Kev cog lus zoo

Txhawm rau kom muab cov khoom zoo, xyuas kom txhua daim ntawm cov khoom zoo meej. Peb nruj me ntsis tshuaj xyuas cov txheej txheem los ntawm cov khoom siv raw khoom mus rau qhov kawg khoom xa tuaj thiab txhua kauj ruam yog tus saib xyuas los ntawm cov kws tshaj lij. Cov neeg ua haujlwm tsim khoom thiab QC engineers kos npe rau Daim Ntawv Pov Thawj Zoo nrog lub tuam txhab. Lawv cog lus tias lawv yuav muaj lub luag haujlwm rau lawv txoj haujlwm thiab cov khoom uas lawv tsim yuav tsum zoo.

peb cog lus tias:

1. Cov khoom ntawm peb lub Hoobkas yog nruj raws li cov neeg siv khoom xav tau thiab lub teb chaws tus qauv GB / T2694-2018 《Technical Conditions for Manufacturing Transmission Line Towers》, DL / T646-1998 《Technical Conditions for Manufacturing Transmission Line Steel PipeNcej》 thiab ISO9001 -2015 kev tswj xyuas qhov zoo.

2. Rau cov kev cai tshwj xeeb ntawm cov neeg siv khoom, lub tuam txhab kev lag luam ntawm peb lub Hoobkas yuav ua cov duab kos rau cov neeg siv khoom. Tus neeg siv khoom yuav tsum paub meej tias cov duab kos thiab cov ntaub ntawv qhia tau raug lossis tsis yog, tom qab ntawd cov txheej txheem tsim khoom yuav tsum raug coj los siv.

3. Qhov zoo ntawm cov khoom siv raw yog qhov tseem ceeb rau cov yees. XY Ntauwd yuav cov khoom siv raw los ntawm cov tuam txhab tsim tau zoo thiab cov tuam txhab hauv xeev. Peb kuj ua qhov kev sim ntawm lub cev thiab tshuaj lom neeg ntawm cov khoom siv raw kom paub tseeb tias qhov zoo ntawm cov khoom siv raw yuav tsum ua tau raws li lub teb chaws cov qauv lossis cov kev xav tau ntawm cov neeg siv khoom. Tag nrho cov khoom siv raw ntawm peb lub tuam txhab muaj cov khoom tsim nyog daim ntawv pov thawj los ntawm steel-ua lub tuam txhab, thaum peb ua cov ntaub ntawv nthuav dav txog qhov twg cov khoom raw khoom los ntawm

Pob

Txhua yam lus nug, thov koj xav sab laj!